Carbon Dioxide Removal Explained

Contents

- Afforestation and Reforestation (A/R)

- Bioenergy with Carbon Capture and Storage

- Biochar

- Bio-oil

- Macroalgae

- Soil Carbon Sequestration

- Wood in Construction

- Direct Air Capture

- Enhanced Weathering

- Ocean Alkalinity Enhancements

- Mineralisation

- Carbon in Concrete

CDR is commonly grouped into two categories: biological and chemical. The first relates to storing CO₂ in biological matter whilst the second involves chemically bonding CO₂ to minerals or geochemically storing it underground. Key CDR methods of capture and storage are as follows:

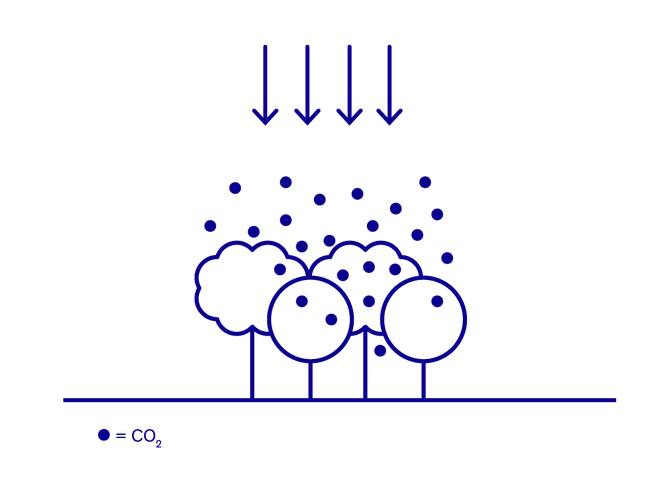

Afforestation and Reforestation (A/R)

A/R is a form of biological carbon removal. Planting biomass increases carbon capture via photosynthesis. Practices include planting new forests, and restoring and planting biomass in areas where biomass has been cut down. By 2050 A/R is expected to sequester 3.6 GtCO₂ per year. A/R is a form of nature-based removal and credits are rated on the BeZero Carbon Markets platform.

Advantages:

Projects can expand, conserve and protect ecosystems.

They can act as erosion control and protect from flooding.

They have potential for a host of environmental and social co-benefits, including increased green spaces, improved health benefits, job opportunities and the potential to protect and enhance biodiversity.

They have potential to be low intervention compared to other removal methods.

Credits are currently purchasable via the voluntary carbon market.

Disadvantages:

Biomass has a saturation point and once reached no more carbon can be removed.

During its growth period, prior to reaching maturity, it is likely less carbon is stored which influences removal capacity. For this reason, avoided deforestation projects, an emissions reductions strategy, will likely capture more CO₂ in the near term than A/R.

Projects can promote planting of monocultures that have greater storage capabilities but can have increased threat to biodiversity and habitats.

Removing carbon via biomass has a shorter permanence than other engineered methods.

There is a higher risk of reversal for A/R compared to other methods due to human and natural factors like land use changes or wildfires, respectively. These risks are growing due to population growth and climate change.

Potentially there is risk of competing land use as A/R scales.

Methodologies for measuring sequestration are not standard across projects because removal varies between ecosystems and biomes.

Other Information:

Accessible in the VCM, alongside improved forest management and restoration projects. But removal makes up only 19% of all credits issued. They range in cost from $3-50 per tonne.

There are several regulatory frameworks and policies in different regions that support the conservation and development of forested lands that can be used to support A/R projects.

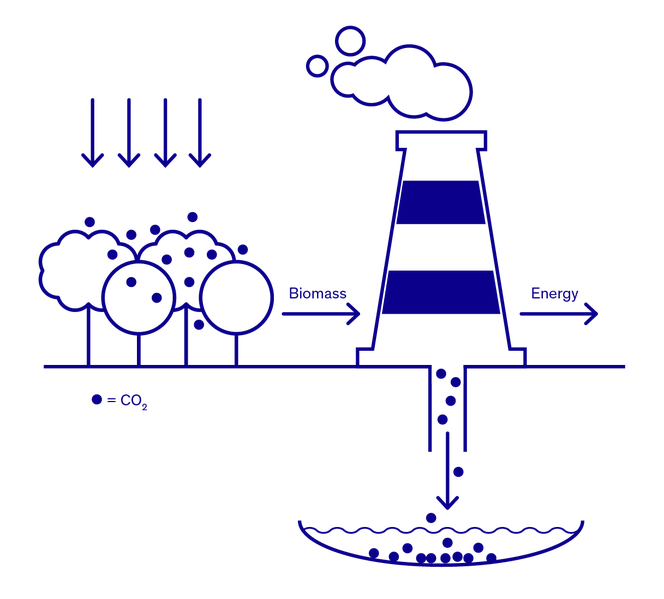

Bioenergy with Carbon Capture and Storage

Bioenergy with Carbon Capture and Storage (BECCS) combines energy production, biological carbon removal and geological storage. It uses biomass in combustion to generate energy, then captures the emitted carbon for geologic injection. Several governments are forecasting bioenergy as an energy supply in a transition away from fossil fuels causing increasing projections for BECCS. IPCC 2050 projections show BECCS contributing 0.5-5 GtCO₂ removal annually with this increasing to 5-10 GtCO₂ by 2100.

Advantages:

Projects can expand, conserve and protect ecosystems.

Geologic storage has an estimated permanence of over 1000 years.

The primary purpose of energy production can contribute to global, sustainable energy security.

The biomass used in combustion can be sourced sustainably, thereby preventing release of carbon through natural decomposition.

It can use waste from landfills for the combustion process, Energy from Waste (EfW), which can help manage growing landfill challenges.

Disadvantages:

It can create competition for land use with food production, placing pressure on food security and potentially causing food prices to rise.

It can increase the use of fertilisers.

It can prompt monocultures that are easier to grow, but potentially reduce biodiversity.

Growing biomass and operating industrial facilities can have high water demand.

Building the CO₂ transportation infrastructure can be expensive and resource intensive.

Example suppliers: Biorecro, Drax, Stockholm Exergi

Purchasers and Financiers:

As BECCS provides both energy and removal it receives large support from public funds. In the UK, BECCS is expected to contribute 52 million tonnes in 2050 to the UK’s Balanced Net Zero Pathway, the largest of any removal technology. As such, the government has provided significant funding to support the development of industrial clusters that see heavy emitting sectors benefiting from one another in an effort to decarbonise, with BECCS facilities central to these clusters.

Other Information:

Per tonne of removal BECCS costs $15-$400 dependent on the project.

Credits are not currently purchasable in the voluntary carbon market.

Public sector or regulatory support:

In the US the Renewable Fuel Standard and the California Low Carbon Fuel Standard both provide tax credits per ton of removal, helping to lower the cost of BECCS.

In the UK the Industrial Strategy Challenge Fund, which is a mix of private and public funding, is supporting the development of these facilities in the industrial clusters. To manage the risks from biomass production the UK government is funding the Biomass Feedstocks Innovation programme.

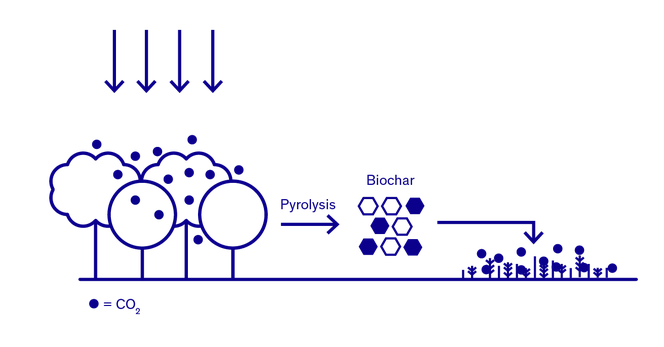

Biochar

Biochar uses biological carbon removal. When biomass and other organic materials are burned in a low oxygen environment, a process called pyrolysis, the carbon inside the biomass transforms to a state where it cannot decay - known as biochar. It is then spread over soil or buried to store carbon in the land. Biochar is projected to remove 2-4 GtCO₂ annually by 2050 according to the IPCC.

Advantages:

The permanence of biochar ranges based on supplier, but it can be as high as 500 years or more.

Biochar can improve soil quality, which in turn improves soil fertility, productivity and crop yield.

By-products of biochar production can potentially be used in asphalt production and the pyrolysis process can produce energy, bioenergy.

Disadvantages:

There is risk of reversal if the project site is disturbed, either by human factors like land use change or natural factors like flooding.

Sourcing sustainable biomass at scale can be challenging.

The pyrolysis process can produce particulate matter that can potentially contribute to health and environmental impacts.

It is quickly emerging and its implementation increasing, but common methodologies for verifying how much carbon is removed do not exist.

It is still a developing technology and remains an expensive credit.

Example suppliers: Carbo Culture, Carbofex, Carbonfuture, Echo2, Ecoera, Freres Biochar, Husk, Net Zero, Oregon Biochar, Planboo, and Takachar.

Purchasers and Financiers:

Credit purchasers include Klarna, Microsoft, Shopify and Swiss Re, each partnering with several Biochar developers with varying commitments. Additionally, biochar is sold by Climacrux, Patch and Puro.Earth in smaller transactions to more buyers. Net Zero was a recipient of XPrize funding.

Other Information:

Biochar credits currently range in cost from $100-$590 per tonne.

There are no direct biochar policies or regulations, but several nature based and land management schemes that indirectly can support biochar development.

Public sector or regulatory support:

In the US the Biomass Crop Assistance Program and Conservation Stewardship Program in the USDA Farm Bill provide financial and policy incentives for biochar.

In the UK the GGR-A and GGR-D programmes fund R&D into Biochar utilisation.

In the EU there is the Sustainable Carbon Cycles regulation.

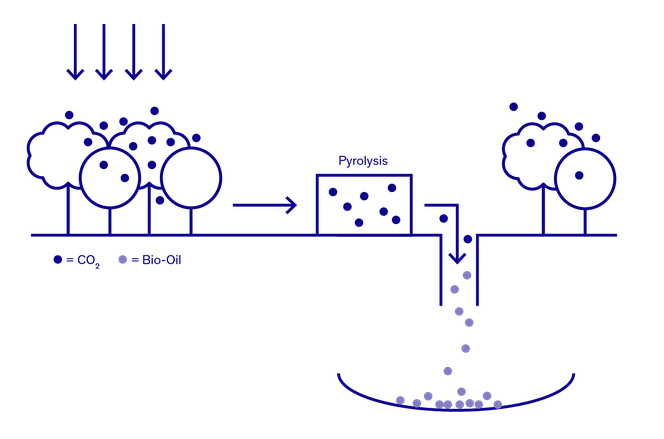

Bio-oil

Bio-oil is a form of biological carbon removal and geological storage. Biomass undergoes a fast pyrolysis process to transform the biomass into an oil: bio-oil. The oil is injected underground into old oil fields where the pressure causes it to solidify. Bio-oil is an emerging, niche carbon removal method developed by few suppliers. Implications towards global removal are not known because it is so emergent and it has not been projected.

Advantages:

Geologic storage has an estimated permanence of over 1000 years.

Suppliers are trying to sustainably source and purchase excess biomass that would otherwise decompose.

Potash produced in the pyrolysing process can improve nutrient content when applied to soils, creating environmental co-benefits.

The process can easily measure and verify injection volumes, making it a provider of ex-post removal credits in the near term.

Disadvantages:

Sourcing sustainable biomass at scale can be challenging.

The pyrolysis process can produce particulate matter that can contribute to health and environmental impacts.

If the biomass needs to be transported from the site of fall to pyrolysis this has associated emissions.

It is still a developing technology and remains an expensive credit.

Example suppliers: Charm Industrial

Purchasers and Financiers:

Aledade, Climacrux, Microsoft, Piva Capital, Shopify, Stripe, Thermo Fisher and Zendesk have all purchased from Charm, and Chan Zuckerberg Initiative (CZI), a US based philanthropy, has provided funding.

Other Information:

Bio-oil credits are currently sold at $600 per tonne.

Public sector or regulatory support: As bio-oil is emergent, no direct support exists. However, geological storage policies for CCS can be used for injection.

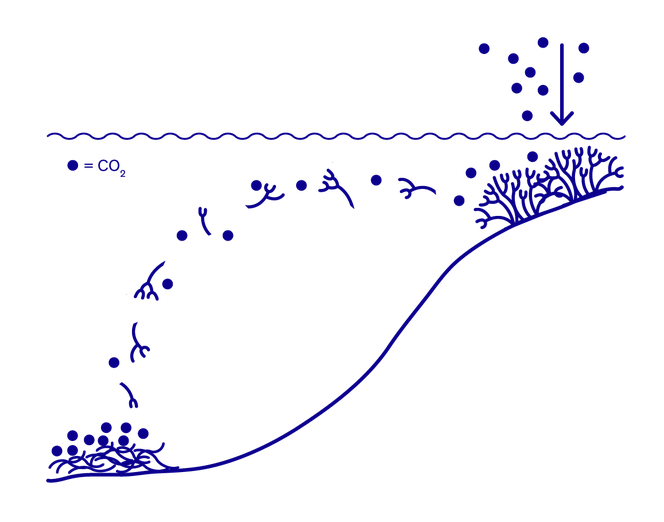

Macroalgae

Macroalgae, a form of marine permaculture or blue carbon, is an ocean-based biological form of carbon removal. Marine ecosystems can store large volumes of carbon removal. These processes nurture macroalgae, or kelp, grown in microfarms to a state of maturity. Some projects have the biomass naturally decay causing it to sink to the ocean floor. Others restore or manage the biomass without requiring sinking. In both it is estimated to permanently store the carbon. Depending on how the algae is managed the advantages and disadvantages will vary. When farmed and managed with technological intervention this is a form of engineered CDR.

Advantages:

Permanence is estimated to be over 800 years for engineered CDR, with variations between projects.

Mature biomass can be used as feedstock in BiCRS productions, act as soil amendments to avoid fertiliser use, and have potential to be food supplements for livestock reducing the enteric methane emissions.

Provides social benefits by improving recreation and tourism opportunities.

Marine ecosystems are one of the quickest degrading ecosystems globally; 2-7% of blue carbon sinks are lost annually. These ecosystems are important for marine biodiversity and can improve water quality. They also are a form of flood protection from coastal storm surges. Macroalgae generation can help reduce the loss of these important carbon sinks.

Disadvantages:

Increasing marine biomass can potentially increase production of non-CO₂ greenhouse gases.

Like terrestrial biomass, macroalgae has a saturation point with a finite amount of storage.

To ensure they are operating as planned without projects growing beyond their bounds or creating externalities, projects need to be monitored and managed, potentially creating operational challenges and costs.

Standardised monitoring, reporting and verification (MRV) remains a challenge as there are large variations between different projects and the end use of the biomass.

Example suppliers: Brilliant Planet, Carbonwave, Climate Foundation, Global Algae, Pull to Refresh and Running Tide

Purchasers and Financiers:

Stripe, Shopify and Piva Capital have all purchased removal credits from RunningTide. The Chan Zuckerberg philanthropy has provided funding to RunningTide. Climate Foundation and Global Algae were both recipients of XPrize Funding.

Other Information:

Credits are currently purchased at around $250 per tonne for engineered macroalgae projects.

Public sector or regulatory support: There is no direct regulation, but there are indirect international policies that are important for operation in international waters (e.g. the Convention on the Prevention of Marine Pollution by Dumping of Waste and Other Matter, and the United Nations Convention on the Law of the Sea). There are also national conservation and land management policies that are applicable to marine-based CDR.

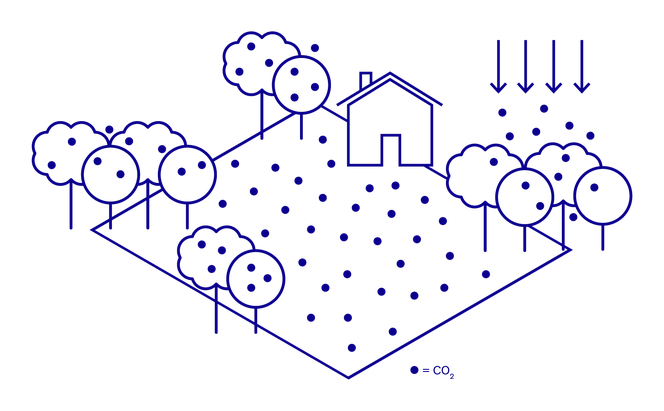

Soil Carbon Sequestration

Soil carbon sequestration (SCS) (a.k.a. carbon farming or regenerative agriculture) uses land-based biological carbon removal. Through multiple methods of land management, soil quality can be enhanced to better absorb and store carbon permanently. These methods include: (1) switching to low-till or no-till practices (till is agitation of the soil by human means), (2) planting perennial crops such as fruit and nut trees and shrubs like currants, (3) changing planting schedules or rotations, (4) managed grazing, (5) applying compost to the land, and (6) water and fire management. SCS practices can also be implemented in wild ecosystems, other than farms, to improve removal potential. By 2050 SCS is expected to contribute 2-5GtCO₂ removal annually.

Advantages:

These practices are established and relatively low touch, making them easy to deploy.

They require few resources or any large-scale infrastructure.

Co-benefits include improved soil health and soil quality, reducing need for fertilisers, increasing crop yields and resilience to weather events, like droughts or flooding. It also has social benefits like increasing job opportunities to manage project developments.

Disadvantages:

Soils, like trees, have a saturation point and finite capacity.

If management ceases, there is potentially risk of reversal.

Some of these practices can increase production of non-CO₂ greenhouse gases like nitrous oxide, nitrogen and phosphorus, which are not accounted for in removal projections.

Land use conflicts can arise if projects need to purchase land from others. If land changes ownership and purpose there is risk of reversal, potentially limiting storage permanence.

Example suppliers: Cargill, Indigo Agriculture, Intuit Earth, Regen Network Development, Soil Value Exchange and Soilfood

Purchasers and Financiers:

Little information is available on the purchasers of SCS credits, but the purchases are often for small-scale credit volumes.

Other Information:

SCS credits are currently sold for about $50 per tonne.

Public sector or regulatory support: There are several regional policies that can indirectly support SCS by promoting land management.

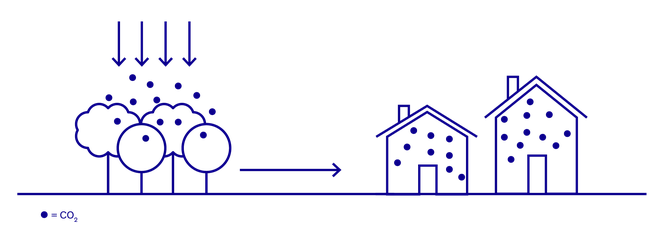

Wood in Construction

Wood in construction (a.k.a. mass timber construction or building with biomass) is permanent storage of land based biological removal. Biomass that is processed and treated for construction purposes can permanently store carbon. Cross-laminated timber, laminated veneer lumber (LVL) and glue-laminated timber (glulam) are all timber products that have been treated intentionally for construction and exemplify the removal potential. One square metre of treated timber can remove 0.15-0.25 tonnes of CO₂.

Advantages:

It avoids the use of steel and concrete products which are more energy intensive and have higher embodied carbon, in industries that are difficult to decarbonise. Reducing the need for these more emitting products potentially would be beneficial.

Timber is a cheaper material to build with and can be quicker to construct.

Products are treated with fire resistant chemicals, preventing fires and removal reversal.

Disadvantages:

Production can potentially incentivise deforestation.

It can exacerbate social challenges currently present in the timber industry, like child labour or conflicts over indigenous lands, by increasing available incentives for timber.

Timber is less durable than steel and concrete, and can be subject to water damage and pest infestation, which can be costly and resource intensive to manage.

Example suppliers: Are Treindustrier, BamCore, Ekovilla, Finnish Log House, LapWall, Moelven Limtre, Termowood and TEWO

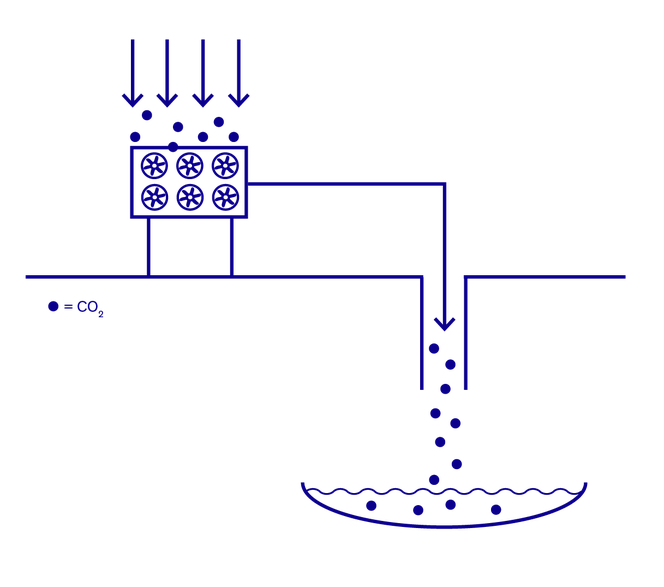

Direct Air Capture

Direct Air Capture and Carbon Storage (DAC, DACCS) removes carbon via geochemical processes and geologic storage. Ambient air is passed through either a solid sorbent or a liquid solvent where the carbon bonds with the material and is fixed. When the sorbent or solvent is heated the bonded carbon is released and directed to permanent storage, either via geologic injection or mineralisation. The carbon captured is pure CO₂ that can then be used in products. Currently 0.1MtCO₂ is removed by DAC annually but this is expected to increase to 0.5-5GtCO₂ per year by 2050.

Advantages:

Geologic storage and mineralisation have an estimated permanence of over 1000 years.

The captured carbon creates a stream of pure CO₂ which can be immediately utilised in other products without having to undergo purification processes.

Potential to be modular, supporting decentralisation of carbon removal.

Disadvantages:

Projects have a large energy demand. This is likely to negate the emissions removed if the energy is not sourced from a renewable supply.

Receiving interest from heavy-emitting sectors who could use the technology as an excuse for high polluting activities.

The technology can be used for enhanced oil recovery, accelerating fossil fuel extraction activities.

Potential CO₂ leakage in transportation from capture to geological storage sites. Potentially exacerbated if DAC were to become modular and increasingly decentralised.

It is a developing technology and remains an expensive credit.

Example suppliers: Carbon Engineering, CarbonCapture, Carbyon, Climeworks, Global Thermostat, Heirloom, Mission Zero, Noya, Sustaera and Verdox

Purchasers and Financiers:

Credit purchasers include Microsoft, Shopify, Stripe and most recently Airbus (who made the largest single offtake purchase of 400,000t from Carbon Engineering). Calcite, Carbyon, Heirloom, Mission Zero and Verdox were all recipients of XPrize funding.

Other Information:

DAC credits range in cost depending on the supplier. They have been sold for $2050-$321 per tonne, although some projections show this will fall to about $100 per tonne by 2030.

Public sector or regulatory support:

In the UK the DAC and GGR Innovation Fund is helping to catalyse start-ups.

In the US, DAC projects can utilise the 45Q tax credit for $50/t removed (on projects over 100,000 tonnes removed per year) and the Low Carbon Fuel Standard credit at $200/t removed. The 2021 Infrastructure Bill announced the creation of 4 DAC hubs with $3.5 billion in funding.

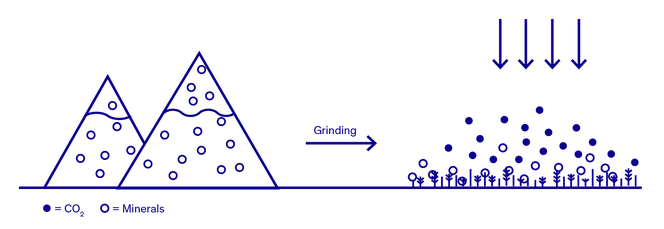

Enhanced Weathering

Enhanced weathering, or enhanced mineralisation, removes atmospheric carbon geochemically. Weathering is a naturally occurring process that converts 1 billion tons of CO₂ into minerals annually. Enhancing this process through human intervention can accelerate the rate of carbon removal. Silicate rocks, such as basalt and olivine, are mined, then undergo a grinding process to form a powder that is spread over large areas of soil. This powder reacts with atmospheric CO₂ to form stable carbonate minerals which permanently store the carbon. By 2050 enhanced weathering could remove 2-4 GtCO₂ annually. When this process takes place in marine environments it is known as ocean alkalinity enhancements, another CDR method.

Advantages:

Estimated permanence of over 1000 years.

The ground minerals provide environmental co-benefits, including improvements to soil health and quality.

The minerals can increase nutrient productivity, increasing soil fertility and providing protection from pests and diseases and reducing the need for fertilisers.

Projects can promote a circular economy, if silicates are sourced sustainably, for example from industry.

Disadvantages:

It is a developing method and remains an expensive credit.

Mining the silicate rocks can be an energy intensive process, generating emissions.

Transportation from mining site to end use is likely to have associated emissions.

As projects scale, the amount of silicate rock needed and produced emissions will likely increase.

Land use changes can reverse the removal. Projects require management to ensure permanence which will have operational implications.

Other social and environmental risks include contamination of groundwater supply, if the rock is not sufficiently weathered it can contain heavy metals which when seeped into water supply can disrupt native ecosystems, water security, and in extreme cases can have health impacts.

The monitoring, reporting and verification (MRV) of these methods remains a challenge.

Example suppliers: Aspiring Materials, CO₂ Zero, Cquestr8, Eion, Future Forest Company, GreenSand, Project Vesta and RockFarm

Purchasers and Financiers:

Many small credit transactions for enhanced weathering are occurring, but the largest buyer is Stripe with purchase of removal from Eion and Future Forest Company.

Other Information:

Credits range in cost from $75-$500 per tonne.

Public sector or regulatory support: There is no direct regulation for enhanced weathering. However, public sector support for R&D, like the UK’s GGR-A and GGR-D programmes, are helping some projects to reach demonstration stage.

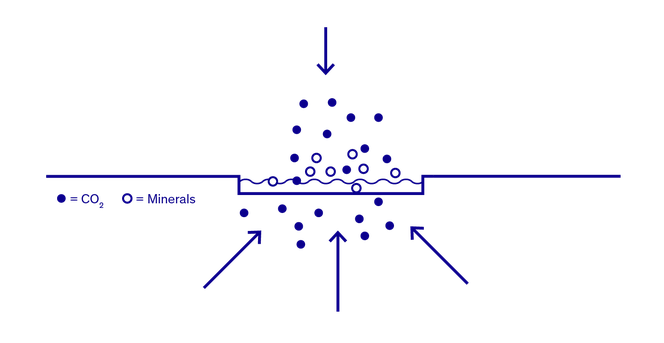

Ocean Alkalinity Enhancements

Ocean alkalinity enhancement (OAE) (a.k.a ocean alkalinisation or ocean liming) is a chemical removal method similar to Enhanced Weathering but in marine ecosystems. Mined and ground silicate rocks, such as basalt and olivine, are spread at the ocean surface, or deposited on beaches and coastal seabeds, where it reacts with CO₂ in the water and in the air to create stable bicarbonates that store carbon permanently. A positive feedback loop is initiated and carbon is further removed by these bicarbonates.

Advantages:

Estimated permanence of over 1000 years.

It provides co-benefits. The minerals can improve water fertility and they can limit ocean acidification (a process escalating because of increasing global temperatures, which causes ocean pH to decline and causing marine ecosystem breakdowns).

Projects that utilise electrochemical processes can produce hydrogen, an energy source.

Projects can promote a circular economy, if silicates are sourced sustainably, for example from industry.

Disadvantages:

It is a developing technology and remains an expensive credit.

It requires large rock inputs, 1 tonne of removal requires up to 3.5 tonnes of material.

Mining can be energy and resource intensive, which has associated emissions from production.

Transportation from mining to ocean sites is likely to have associated emissions.

Providing new minerals to an ecosystem can have impacts on biodiversity, food chains and potentially human food supplies and jobs, if it disrupts fishing practices.

These projects operate in deep waters and are operationally difficult to manage.

The monitoring, reporting and verification (MRV) of these methods remains a challenge.

Example suppliers: Captura, Ebb Carbon, Heimdal, Planetary Hydrogen, Project Vesta, SeaChange and Solid Carbon

Purchasers and Financiers:

Stripe and Shopify are the only current purchasers of OAE credits. Captura and Planetary Hydrogen were both recipients of XPrize funding. Heimdal is part of the first batch of Carbonfuture’s Catalyst.

Other Information:

Credits are currently sold at $1000-$2000 per tonne.

Public sector or regulatory support: There is no direct regulation, but indirect international policies that are important for operation in international waters (e.g. the Convention on the Prevention of Marine Pollution by Dumping of Waste and Other Matter, and the United Nations Convention on the Law of the Sea). There are also national conservation and land management policies that are applicable to marine-based CDR.

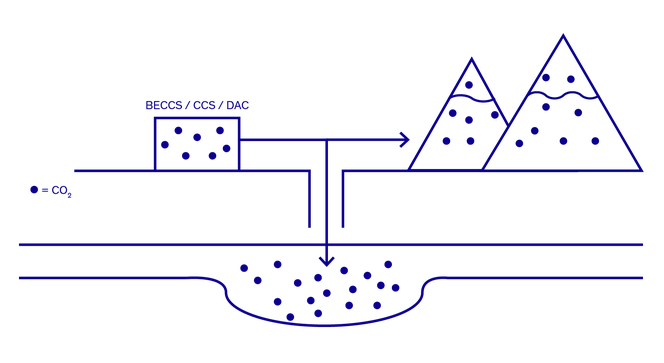

Mineralisation

Mineralisation (a.k.a. mineral carbonation) is a form of geochemical carbon storage. Silicate rocks are converted to carbonates when subjected to high concentrations of CO₂ at high temperature and pressure. Mineralisation is combined with other capture and removal methods, like DAC and BECCS, which capture the CO₂ prior to storage via mineralisation. It can be done in-situ and ex-situ. In-situ methods inject CO₂ below ground into the rock surface and ex-situ requires injection into rocks above the surface. By 2050, it is projected to contribute 1-10 GtCO₂ removal annually.

Advantages:

Estimated permanence of over 1000 years.

Can be used in products, like concrete, to help decarbonise high emitting sectors (see Carbon in Concrete).

The silicate rocks used in these processes can be sourced sustainably from other industries where they would otherwise be wasted, promoting a circular economy.

Disadvantages:

Scaling requires more resources. To store 1 tonne of carbon, 2-3 tonnes of rock is needed.

There can be unsustainable mining practices and increased emissions if these practices are not monitored.

With no safeguards in place environmental impacts can arise, like groundwater leakage caused by heavy metal substances and particulate matter seeping into water supply.

Mineralisation in partnership with other removal methods can become confusing as to which party is counting the removal, creating challenges of double-counting.

Example suppliers: Blue Planet, Cambridge Carbon Capture, Arca, Carbfix, CarbonCure, Carbon8 and 44.01

Purchasers and Financiers:

44.01, Arca and CarbFix have all received funding from the XPrize award. Shopify and Stripe have both made large credit purchases.

Other Information:

Credits have been sold at costs between $130-$750 per tonne.

Carbon in Concrete

Carbon in concrete (a.k.a low carbon concrete) is a form of utilisation that chemically stores carbon. There are three storage processes: (1) mineralisation, (2) curing, and (3) novel approaches. Mineralisation subjects grinded silicate rocks to CO₂ at high temperatures to bond the carbon for permanent storage. Curing uses concentrated streams of CO₂ to accelerate the curing process, resulting in a higher strength material. Lastly, the chemical composition of cement can be adjusted to include CO₂ and other chemicals, altering mechanical properties of the cement. In all these processes the carbon is captured via other CDR methods but stored permanently in the concrete, making this a form of utilisation. Shifting concrete production to include carbon removal is projected to contribute to about 0.1 GtCO₂ of storage by 2050.

Advantages:

Estimated permanence of over 1000 years.

Adding carbon can improve the tensile strength and other mechanical properties.

The cement industry contributes 5% to global annual emissions - this is significant and not expected to decrease as society urbanises. Storing carbon in concrete can help decarbonise this hard-to-decarbonise sector.

Storing CO₂ in the built environment means less natural, rural land has to be used for CDR, preserving rural spaces creating social and environmental benefits.

The high technological intervention of this method means measuring the volume of carbon stored is possible and methodologies are developing to support this.

Disadvantages:

Cement production produces large emissions, even with CDR integrated.

High technological intervention for production, requiring infrastructure and expertise.

Likely limited in scaling as it requires a steady CO₂ stream. Where this CO₂ is sourced will have associated challenges. Using DAC will have high energy requirements, using BECCS will have challenges in sustainable biomass sourcing, and using CCS from fossil production will negate the removal benefits.

Mineralisation in partnership with other removal methods can create confusion as to which party is counting the removal, creating challenges of double-counting.

Example suppliers: Blue Planet, Carbfix, Carbicrete, CarbonBuilt, CarbonCure, Carbon Upcycling, Neustark, Solidia, Vandersanden and VTT Bio-concrete

Purchasers and Financiers:

Few credit purchases have taken place, but include transactions between Neustark and Microsoft, Piva Capital and Verdane. Patch, a carbon removal marketplace, has Neustark credits available for smaller purchases. A recent commitment by Invert and Ripple with CarbonCure, shows increasing interest from smaller investors in this method.

Other Information:

Credits currently sell at around $400 per tonne.